ReverteTM has been used for many years in a wide range of applications, listed below is just a small example of where ReverteTM has been successfully utilised and how it has improved the product offering.

In a quest for improving the environmental credentials of the checkout bag Wells Plastics have worked with Brand owners to develop an optimised ReverteTM system which will give a the highest technical performance at a cost effective price.

The use of ReverteTM has complimented well many supermarkets who are aware of the drivers to be more environmentally conscientious, whilst providing their customers with what they need.

excellent carbon footprint

Many studies have shown that the use of the checkout bag has an excellent carbon footprint when compared to many possible alternatives including paper sacks. The use of a high ratio of recycled material and CaCO3 make these bags less of an environmental burden than many people would have us believe!

Using a checkout bag offers the consumer a convenient way of carrying their goods from the shop, and a bag which can be used for a second time, either to collate trash or recyclate. It has been shown in a number of studies that banning checkout bags sends the sales of bin liners and trash bags through the roof, hardly a reduction in the use of plastics that such a ban is intended to achieve!

less primary packaging

Continuing to use checkout bags also gives the retailer the opportunity to have less primary packaging on their goods and to advertise their shop and/or goods to a wider audience.

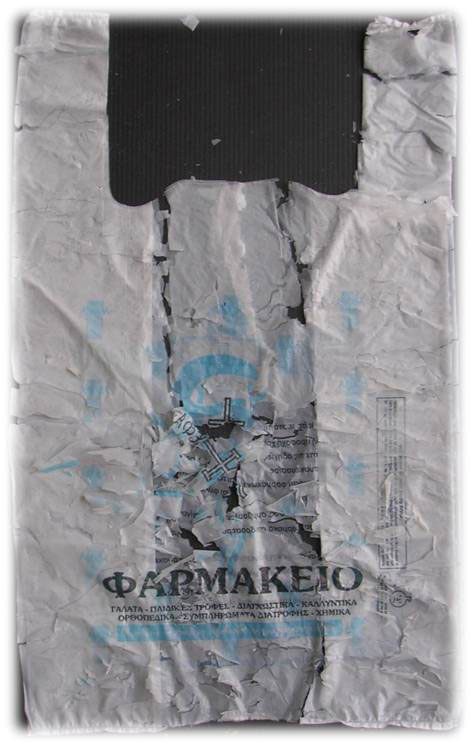

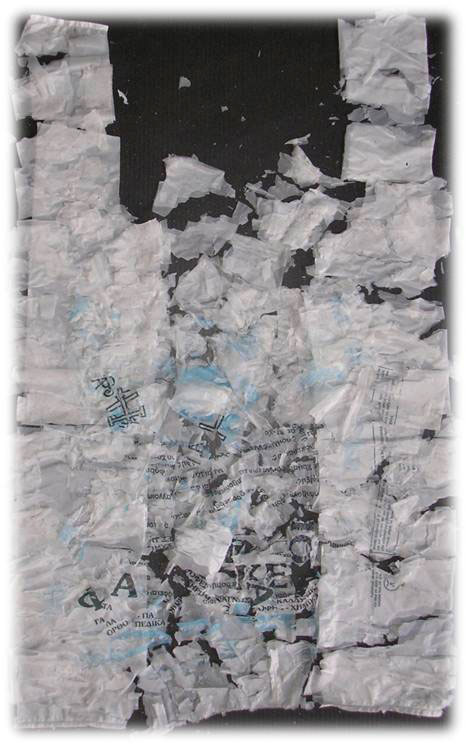

ReverteTM when incorporated into the checkout bag at the point of manufacture ensures that if the bag at the end of its useful life is irresponsibly discarded, will not pose a long term environmental problem or hazard.

The formulation is devised to allow sufficient time for the bag to become part of a collection scheme and recycled into another application such as artificial timber planks, or for it carry out a second task such as waste bag then rapidly degrade.

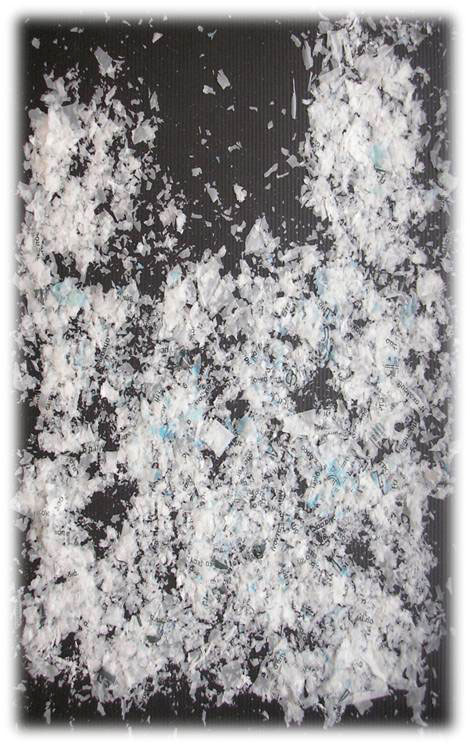

smaller biodigestible materials

Once the initial stage of degradation has occurred the bag will have micro fragmented, transformed from long polymer chains to much smaller biodigestible materials. In a viable bacterial environment these small molecular species will be consumed, converting into CO2, H2O and biomass.